News | Industrial Combustion Equipment

All the latest News on our company

Portable incinerator furnaces for the treatment of hospital waste and corpses

Posted on: 27 / 05 / 2020 | 0 Comentarios | Tags: Containerised incinerators, E&M Combustión, hornos crematorios, Hornos incineradores portátiles, Hospital waste treatment, Portable incinerator, Portable incinerator furnaces, Tratamiento de residuos hospitalarios

E&M Combustion has launched the design of portable incinerator furnaces for the treatment of hazardous hospital waste and corpses. Spanish engineering company, specialized in the development of Combustion Technologies, thus applies its experience in fixed hospital cremation furnaces to new requirements arising from the COVID-19 pandemic for the ecological incineration of hospital waste and dead corpses, especially in remote or difficult-to-access places.

The range of mobile structures developed by the company brings together several series of capacities of portable incinerator furnaces according to customer demand for use in the cremation of hospital waste, corpses, bone remains and animals from farms and zoos in a fast and effective under maximum hygiene conditions.

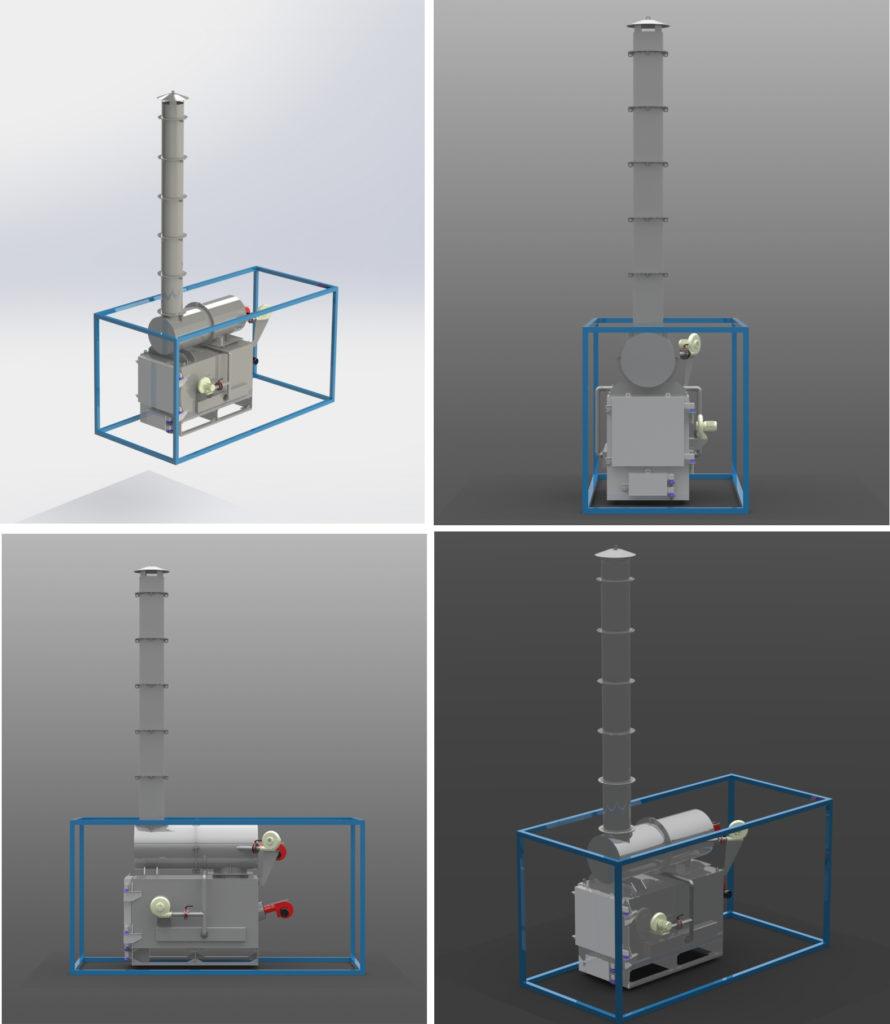

The design of the equipment thus enables E&M Combustion to supply compact portable container-type units made up of all the necessary elements for immediate start-up. The container is prepared to be transported by truck to the workplace and can be assembled and disassembled with a crane.

The launch of this range of portable incinerator furnaces is based on the previous experience of Spanish engineering company, in the start-up program of fixed incinerator furnaces developed for Cuban hospitals in collaboration with the Ministry of Health (MINSAP) of this country.

The standard container that houses the incineration units has dimensions similar to a 20 ”container, but with a little more height, around three meters. The usual dimensions of the unit are 6m x 2.3m x3m. It is equipped with the necessary luminaire for proper operability indoors and an air conditioning installation.

Efficient technology, without polluting emissions

The new portable incinerator furnaces developed by E&M Combustion consist of a mobile system designed under conditions that allow reliable and ecological technology to operate, without producing emissions of polluting particles, so that combustion is efficient and maintains rigorous control of the incineration, for which it has a double incineration chamber. The equipment complies with the hygienic-sanitary regulations to perform the operation in the maximum hygiene conditions.

The container also houses a diesel tank inside that guarantees a minimum of six incinerations in a row, equivalent to its operation during a day. The duty cycle can last from 90 to 150 minutes, depending on the material to be treated. In the specific case of pathological waste, this cycle is 90 minutes.

The tank has a loading mouth to fill it continuously. The piping connections to this reservoir are factory pre-installed in a modular fashion as are the piping lines for the fans.

Portable waste incineration units consist of:

- Incineration chamber

- Thermal reactor

- Chimney

- Electric panel of command and automated control of equipment functions

- Self-supporting structure (container) that can be transported through a truck or trailer

Fuel tank with autonomy for 6 daily cremations

Description of the elements of portable incineration furnaces

The incineration chamber is made up of a 10mm carbon steel plate orthohedron thick, with reinforcements and flanges of the same thickness. The interior of the chamber is lined with insulation material, which in turn is coated with galvanized sheet metal.

The introduction of the remains or corpses is carried out through a hinged main door projected with 6 mm. thick, also lined with heat insulating material. The extraction of the waste, already turned into ashes, is carried out through a secondary door below the main one, made with the same materials and thicknesses as the chamber. This ash extraction door is also used for the total cleaning of the chamber.

The air necessary for combustion is supplied by an electric fan and is conducted through ducts arranged along the chamber, at the bottom, which are supplied by a collector located under the furnace body.

Incineration chamber dimensions:

Inside

Length: 2750 mm

Width: 1200mm

Height: 1150 mm

The dimensions provide a volume of 3.24 m3, which means a wide capacity to treat hospital waste, with an average total weight of 250 Kg / cycle or corpse, including the coffin.

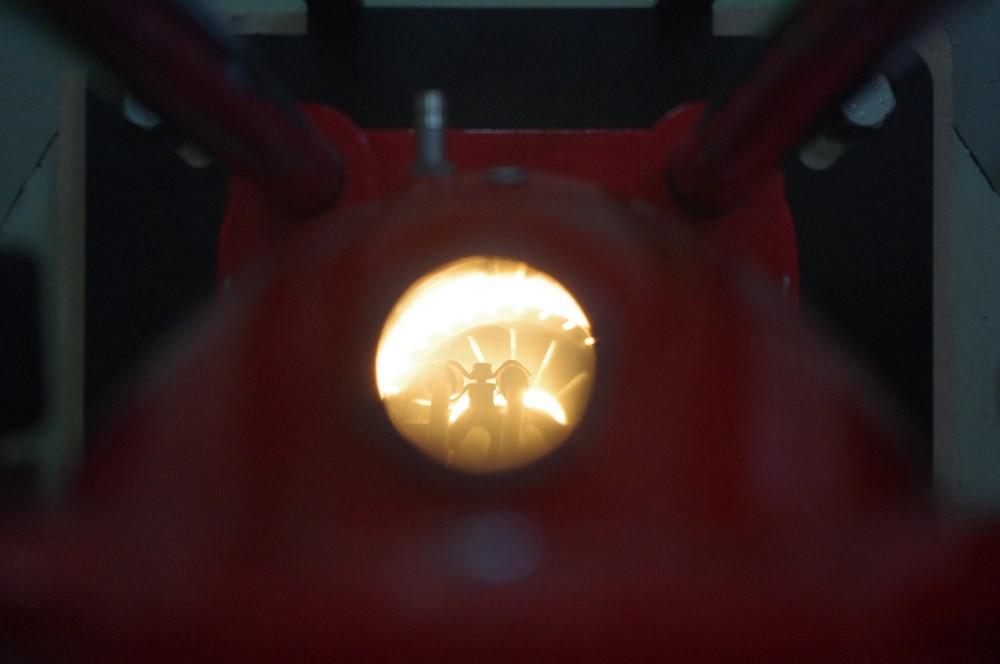

The chamber consists of a pressurized burner that provides the necessary heat for proper incineration of the waste. The chamber temperature is 750ºC – 850º C, although it can be adjusted up to 1200ºC for class III waste treatment.

Thermal reactor characteristics

The oxidation of the gases produced in the incineration chamber is carried out in the thermal reactor, located above the chamber and attached to the gas evacuation chimney.

The reactor is cylindrical and constructed of 5mm sheet steel. thick, located at the top of the combustion chamber.

The air necessary for the oxidation of the gases is supplied at a suitable pressure by an electric fan. A set of self-acting valves enables convenient flow regulation. Thus, air is injected into the reactor by means of a tangential crown, which in turn causes the appropriate turbulent regime for oxidation to occur.

A pressurized burner provides the necessary heat for the oxidation to take place at the expected temperature of 1000-1100ºC.

The gases produced in the reactor are completely transparent and free of odors. It is not necessary to adopt additional measures for gas cleaning and / or particle filtration. The useful internal volume of the afterburner of 0.82 m3 allows the gases to remain at the temperature of 1,000ºC for a minimum of 2 seconds, in accordance with the provisions of environmental legislation.

Thermal reactor dimensions:

Outside diameter: 1050 mm

Inner diameter: 750mm

Length: 2750 mm

Chimney

The chimney is built in different cylindrical sections made up of an inner sheet of stainless steel refractory and an outer one, between which a fireproof refractory material is placed to prevent the temperature from escaping to the outside. The stainless steel refractory used protects the sheet metal inside the cylinder from the high temperature action of the furnaces against acid corrosion that can form with cold fumes and very high sulfur fuel contents.

The chimney incorporates standardized tabs for measuring pollutants, as well as supports for coupling the isokinetic probe, with a diameter of 60 mm. The standard height of the chimney is 6500 mm from the base of the incineration chamber. Likewise, depending on the place and the sampling, the necessary height can be calculated, adding sections to it.

The various sections of the chimney can be placed with a crane or manually.

Components of the incineration chamber

The selected burners are the EM 30 LO2 models for the combustion chamber and for the pressurized reactor and operate mainly on diesel.

Technical description

1- Compact diesel burner, with two-speed operation, fully automatic. The regulation of the air is carried out by means of a hydraulic hammer that is actuated when the second speed solenoid valve enters.

2- The fan impeller, with a high static pressure, makes the burner operation insensitive to oscillations in the boiler gas overpressure.

3- The burner is supplied with the electrical control panel incorporated and fully electrically wired.

- Temperature probe

The burner has two K-type probes with a built-in display that allows real-time temperature viewing, in addition to reading on the 15 ”tactical screen.

- Fan motor group

The equipment consists of 3 fans. Two of the centrifugal type that generate the air necessary for the work of the combustion chamber and the reactor or afterburning chamber.

Fixed incinerator furnaces

In 2012, E&M Combustion began a collaboration with the Cuban Ministry of Health (MINSAP) for the construction of hospital waste incineration furnaces and their automation, coinciding with the generation of the debate on the environment in that country. The operation involved the entry of the company in areas where it was not previously introduced, through the provision of high technological level solutions.