Combustion air preheaters SICAPH

Improve environmental, technical and economic performance

SICAPH: Combustion air preheaters

For some years now, the Combustion Air Preheaters (APH) are used in industry in boilers and furnaces due to its performance enhancing qualities, driven at the time by belong to the technological package of energy efficiency improvement recommended by the US Department of Energy.

Characteristics of SICAPH preheaters

SICAPH combustion air preheaters designed by E&M Combustión allow the transfer of heat from the gases of outgoing combustion air to the fresh air entering the burner or combustion hearth.

- They reduce polluting emissions

- They reduce the chimney outlet temperature

- They save fuel

- They are easy to maintain

- They do not affect the operation of boilers or furnaces

Design seeks to balance parameters, such as:

- Lowest pressure drop in order to avoid the system draft choke both on the flue and supply side

- Higher turbulence as possible to reach thermal efficiency above this kind of systems usual average

- Light and robust

DESIGNED TO OPERATE WITH ALL TYPES OF FUELS

| Diesel or Gas Oil | Biomass and/or Wood | Natural Gas |

|---|---|---|

| Light fuel | Pellets | Biogas |

| Heavy fuel | Coal | Hydrogen |

Air preheaters for greater energy efficiency

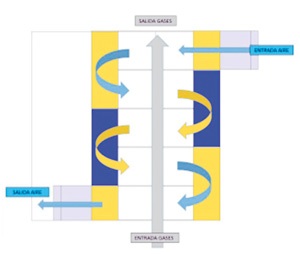

The fresh air circulates inside the pipes while the exhaust gases circulate through the smoke chamber.

The fresh air conduction pipes are of the finned type (equipped with crimped fins on the outside of these) which increases the turbulence of the exhaust gases and the heat exchange surface of the equipment.

Fresh air finned tubes are configured in line and in compact blocks to achieve a high coefficient transmission and drastically reduce the temperature of the exhaust gases.

The gas casing is made of a premium quality cabon steel sheet suitably reinforced and arranged to avoid sealing failures.

SICAPH preheaters, European quality

SICAPH combustion air preheaters are fully assembled in our workshop, allowing precise quality control and conforming to our standards and design codes.

Supplied finished with a protective anti-heat coating that prevents corrosion for many years.

SICAPH, adapted to your needs

Upon customer request, SICAPH preheaters can be equipped with the following ítems:

- Support frame

- Thermal isolation

- Custom painting

- Valves or Damper by pass

- Instrumentation

- Automatic cleaning system

MAIN BENEFITS OF SICAPH PREHEATERS

ECONOMIZERS vs. PREHEATERS

There is a general trend in the market to install economizers rather than combustion air preheaters. This is often a mistake, since economizers can generate certain problems that preheaters do not, especially when they are not designed for the actual consumption of the boiler, or serving in an operation with frequent starts/stops or with frequent fluctuations in thermal demand, whether it is steam or heat.

In most of the economizers in the plants in which the boilers work periodically at low loads, condensation occurs associated with the decrease in the temperature of the gases. These condensations end up over time causing damage to the economizers and continuous repairs to them, causing their performance to drop drastically, with the economic damage that this entails for the customer. This problem is more common, so in many plants the economizers have a rather short half-life and their effectiveness is in question.

This problem does not occur in an air preheater, since the exchange takes place between combustion gases and air and there is always a flow ratio that prevents this phenomenon from ocurring. The average life and durability of air preheaters is generally much longer than that of economizers in general and is therefore one of the issues to take into account when looking for an energy saving system in boilers.

Economizers are not always more profitable!

PROFITABILITY OF THE INSTALLATIONN

Experience obtained up to date in plants with continuous consumption such as paper mills or ertain food industry shows an amortization of the installation in less than 2 years. In any case, we advise you to consult our specialists about the returns of estimated investment for each specific plant.

Profitability from the beginning!

Documents (PDF)

POLLUTANT EMISSIONS REDUCTION SYSTEMS

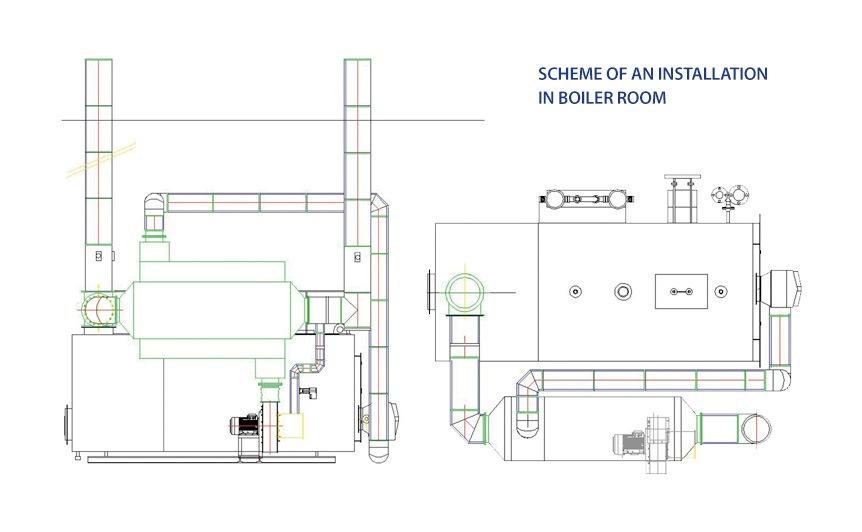

One of the main additions that we provide in air preheating facilities is the installation of an F.G.R. (Flue Gas Recirculation) to reduce emissions. This system is included as complement to the installation of a hot air burner model JBD, which already incorporates the latest technologies in NOx reduction. In this way, the sum of these two elements/systems causes NOx emissions to be achieved with natural gas below 60 mg/Nm3 fully complying with the most demanding regulations established in these moments in the E.U.

The advantage of this system is that with the installation of a single duct to achieve these said results. That is, we take advantage of the installation of the preheater and the hot air ducts together, to implement the F.G.R. system. It achieves system being truly ecological, efficient and therefore profitable.

If you are looking for reducing your emissions and changing the burner for this purpose, think about This system can make your green investment pay off in a short space of time!

E&M Combustión develops and installs the SICAPH combustion air preheater systems.

Call us if you want more information.