Hydrogen Burners

Industry decarbonization

Hydrogen Burners. Industry decarbonization

E&M Combustión provides advice, design, manufacture and commissioning of Hydrogen Burners and Hydrogen Combustion Systems in power generation plants and industrial processes, consistent with its role as an international benchmark in advanced combustion technologies, and its experience in this area.

Why to use Hydrogen Burners?

Due to their important role in the energy transition, our hydrogen burners are already operating in chemical and petrochemical plants, allowing greater efficiency of the boilers and reducing emissions.

The challenge of transforming the energy model through the use of hydrogen comes to industry to provide new tools to eliminate CO2, which is largely responsible for climate change. This milestone is a great opportunity for the planet as a whole, and for the improvement of production processes, although it requires the accompaniment of a technological partner and specialized attention to the combustion challenges that this new fuel brings with it.

For E&M Combustion, innovation is the basic objective and the fundamental pillar on which the company is based. Within the Hydrogen value chain, E&M Combustion continues to work on the development of Combustion Systems that are increasingly respectful of the environment, adapting to technological innovations in the environment with the aim of helping to make combustion sustainable in the industry. The company continues to develop efficient, safe and less polluting hydrogen combustion technologies, a field in which it has previous experience. With this objective, its Hydrogen burners are adapted to the needs of customers, to whom they provide specific efficient and ecological solutions in their industrial combustion processes.

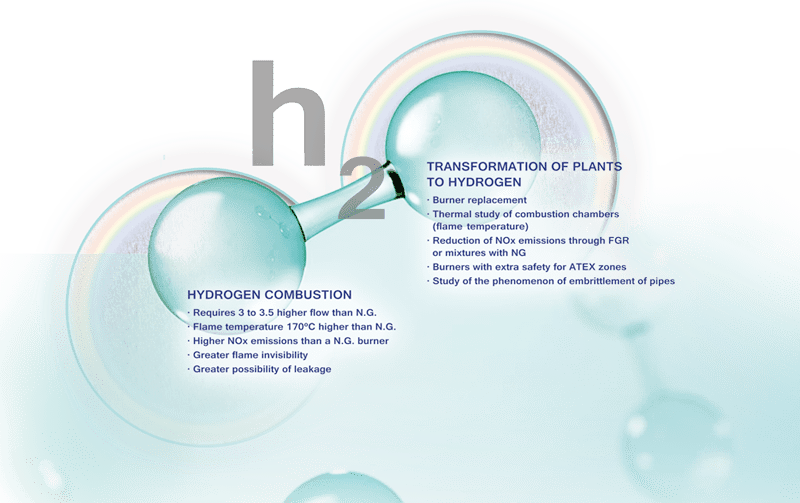

Main challenges in hydrogen combustion

In the absence of new power plants or industrial plants designed specifically for the combustion of this fuel, a great challenge we face is the transformation of plants that now operate with natural gas, fuel oil, diesel or coal for use with hydrogen. This requires the development and application of reliable technology of combustion equipment and installations:

- Redesign and adaptation of supply pipes

- Hydrogen burners that prevent high gas velocities at the injection points

- Calculation of the possible speed of a backfire

- Flame temperature drop

- Study of the adaptation of flames in different hearths

- Flame geometry control

- Study and limitation of NOx emissions

E&M Combustión guarantees with its experience and technology in the combustion sector the success in the incorporation of hydrogen in production processes

Methods to reduce polluting emissions

- A · Gas recirculation. NOx reduction technologies through gas recirculation in order to reduce nitrogen oxides. It is an excellent formula to protect existing equipment and guarantee them a superior life time.

- B · Blend with natural gas. This alternative is also tested by E&M Combustión and it is very viable for the future. It consists of mixing hydrogen gas with 15% -20% natural gas. The enriched mixture increases the calorific value and achieves a more stable and efficient combustion. In addition it also allows to improve flame detection. There are two alternatives for mixing, either through a mixer or in the burner itself, through two different gas ramps.

Aspects to take into account in the design of hydrogen burners and hydrogen combustion systems:

![]() Low hydrogen density. Although the design of hydrogen nozzles and injectors are similar to those of other gases, they must not exceed high speeds at the injection points. Furthermore, it is necessary to calculate the possible speed of a backfire.

Low hydrogen density. Although the design of hydrogen nozzles and injectors are similar to those of other gases, they must not exceed high speeds at the injection points. Furthermore, it is necessary to calculate the possible speed of a backfire.

![]() High flame temperature.The flame temperature obtained with hydrogen is higher than that obtained with natural gas (approximately 170ºC higher than NG). The study of lowering the temperature is imposed to avoid the deterioration of the hearths.

High flame temperature.The flame temperature obtained with hydrogen is higher than that obtained with natural gas (approximately 170ºC higher than NG). The study of lowering the temperature is imposed to avoid the deterioration of the hearths.

![]() Pollutant emissions. Hydrogen does not emit CO2 on combustion, but it does emit NOX. This is one of the factors to be worked on in the coming years, as it could exceed the values allowed by the EU for medium and large power installations.

Pollutant emissions. Hydrogen does not emit CO2 on combustion, but it does emit NOX. This is one of the factors to be worked on in the coming years, as it could exceed the values allowed by the EU for medium and large power installations.

![]() Flame detection. One of the great challenges we face with hydrogen is the invisibility of its flames. E&M Combustion proposes the incorporation of specific systems for its detection, either through special polarized glasses or thermal imaging cameras. Incorporation of sensors in the burners as a safety measure and sensors capable of detecting flickering.

Flame detection. One of the great challenges we face with hydrogen is the invisibility of its flames. E&M Combustion proposes the incorporation of specific systems for its detection, either through special polarized glasses or thermal imaging cameras. Incorporation of sensors in the burners as a safety measure and sensors capable of detecting flickering.

![]() Leaks. Hydrogen safety. The hydrogen molecule is smaller than that of other fuels, so it increases its leakage capacity in pipes and valve connections. To minimize the risk of explosion, a good alternative is to manufacture the burner and the gas lines with elements that comply with the ATEX anti-explosion regulations. E&M Combustion has been successfully carrying out this type of manufacturing for many years for sectors such as petrochemicals, refineries, etc.

Leaks. Hydrogen safety. The hydrogen molecule is smaller than that of other fuels, so it increases its leakage capacity in pipes and valve connections. To minimize the risk of explosion, a good alternative is to manufacture the burner and the gas lines with elements that comply with the ATEX anti-explosion regulations. E&M Combustion has been successfully carrying out this type of manufacturing for many years for sectors such as petrochemicals, refineries, etc.

Video

Documentation (PDF)

E&M Combustión manufactures you custom hydrogen burner . Call us for more information.