News | Industrial Combustion Equipment

All the latest News on our company

Installation of a Regenerative Thermal Oxidizer (RTO) in a US chemical plant

Posted on: 16 / 08 / 2022 | 0 Comentarios | Tags: E&M Combustión, Environmental protection system, Installation of a regenerative thermal oxidizer, RTO

E&M Combustión completes the installation of a Regenerative Thermal Oxidizer in a chemical plant in the US. Commonly known as RTO, it is an oxidation technology aimed at increasing environmental protection.

To achieve these objectives, the Regenerative Thermal Oxidizer installation has a high-temperature burner, capable of decomposing Hazardous Air Pollutants (HAP), formed by the incomplete incineration of fuels such as coal, oil, gas, or wood, garbage and other organic substances. The high temperatures achieved will also treat volatile organic compounds (VOC) and emissions such as CO2.

The elimination of these hazardous contaminants is achieved through the process of heating the exhaust air, which allows a high destruction efficiency to be achieved, burning these organic compounds at high temperatures.

The oxidation technique is most frequently used in industrial applications, such as chemical and petrochemical manufacturing, oil and gas, pulp and paper, construction materials, wastewater treatment and lumber production…

Installation of a Regenerative Thermal Oxidizer

Installation of a Regenerative Thermal Oxidizer

The operation of a regenerative thermal oxidizer installation is based on the passage of air loaded with VOCs generated in the plant process itself, which is introduced into the thermal oxidizer with the help of a fan. Thus, the effluent is heated in the inlet tower, passes through the combustion chamber, and is finally cooled in the outlet tower.

Optimum operation is achieved by maintaining a high operating temperature, with a suitable minimum residence time in the combustion chamber and adequate turbulence to achieve the most suitable mixture of effluent and oxygen.

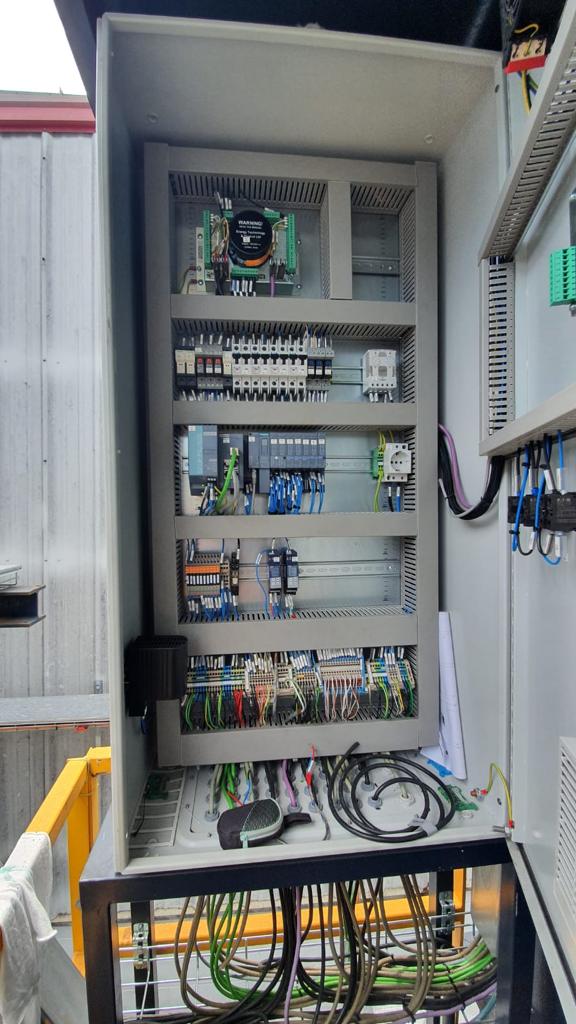

In addition to the combustion chamber or the necessary burners, the installation is made up of the effluent transfer fan, the heat storage tower, the automatic valve system and a PLC control panel and interface screen.

The installation of a thermal oxidizer is usually a common procedure, and growing, in plants committed to protecting the environment, by eliminating volatile chemical components dangerous to the health of the planet. In addition, among its advantages are its high efficiency and low NOx levels, as well as the continuous control of emissions. They lead to reduced fuel consumption and easy maintenance and management.