News | Industrial Combustion Equipment

All the latest News on our company

News

Archive

Other Content:

Tags

Combustion chambers – Hot gas generators

Posted on: 22 / 01 / 2023 | 0 Comentarios | Tags: cámaras de combustión, Combustion Chambers, drying processes, Duct burners, E&M Combustión, gas, gas duct burners, generador de gases calientes, heat exchange, Hot gas generators, industrial applications, Low Nox burners, Pressurized air burners, procesos de secado, quemadores de aire presurizado, quemadores de conducto, quemadores Low Nox

Hot Gas Generators are compact combustion chambers used in a large number of industrial applications, such as cement manufacturing, mineral drying, wood industry, food industry, chemical industry or drying processes. These units produce gases at different temperatures starting from the combustion of different fuels such as natural gas, diesel, fuel oil, etc. (Extract from the E&M Combustion Technology Conference in Knauf Surabaya).

The internal combustion chambers are covered with refractory to withstand temperatures up to 1500 º C and have a robust structure and resistant to this type of industrial applications. There are different types of chambers with single or twin shell that makes the heat losses through them quite small.

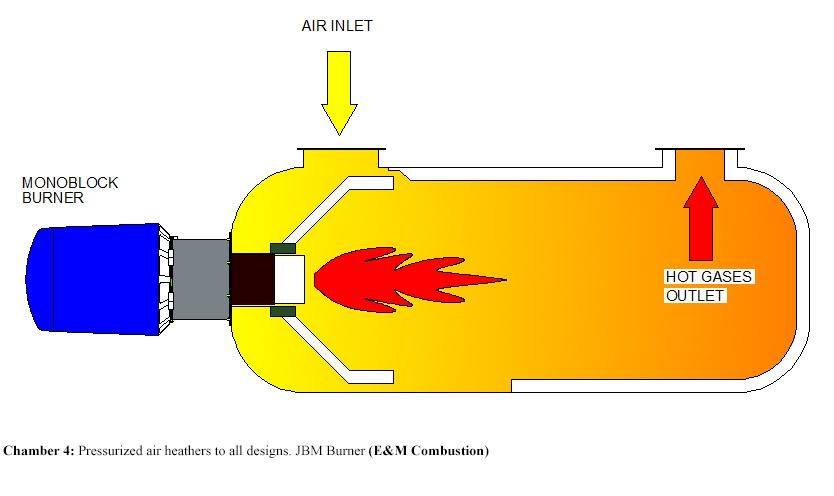

In order to generate these hot gases, industrial burners of various types are used. The most common of which are the pressurized air burners, for liquid fuel and gases, and also gas duct burners are used.

Principle of operation of the Combustion Chambers

Hot gas generators are used in different industrial processes and their objective is to generate gases at a certain temperature for drying, heat exchange, etc. The process consists in using a burner to generate a determined volume of gases. A dilution air blower is then used to cool the gases to the process temperature and increase the gas flow rate to the desired volume. This mixture is performed in a refractory-lined combustion chamber to minimize heat losses.

Depending on the type of application and with the aim of increasing the performance even further, a part of the gases used in this process is introduced back into the combustion chamber, thereby increasing the performance of the system by reducing the heat losses.

Characteristics of E&M Combustion Generators

• Capacity from 1 to 100 MW

• Different types of fuels, natural gas, fuel oil, gas oil, biogases, recycled oils, wood pellets, etc.

• Blend of various fuels

• High thermal efficiency

• Units pre-assembled packages

• Low maintenance costs

• Fully automated control

• Low NOx burners

• Quick response to process demand

Types of Burner and Combustion Chambers for Hot Gas Generators

For the processes where natural gas is used we can highlight two types of burners and applications that are the most used and described below.

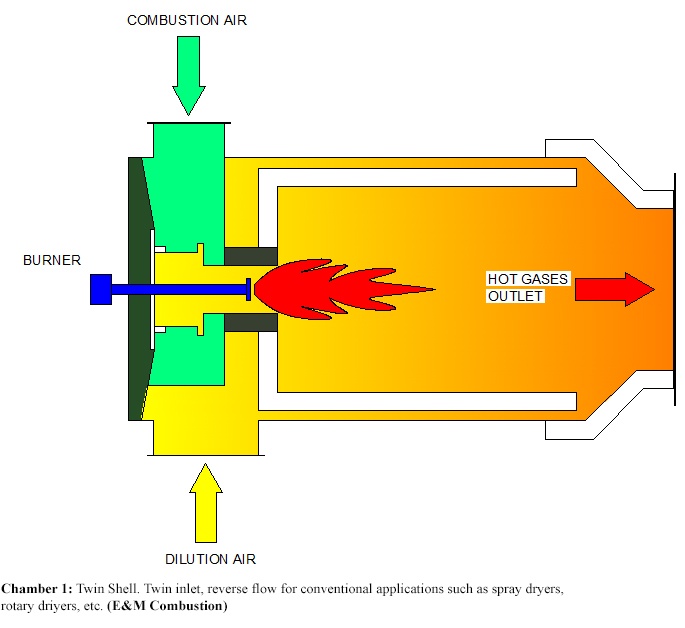

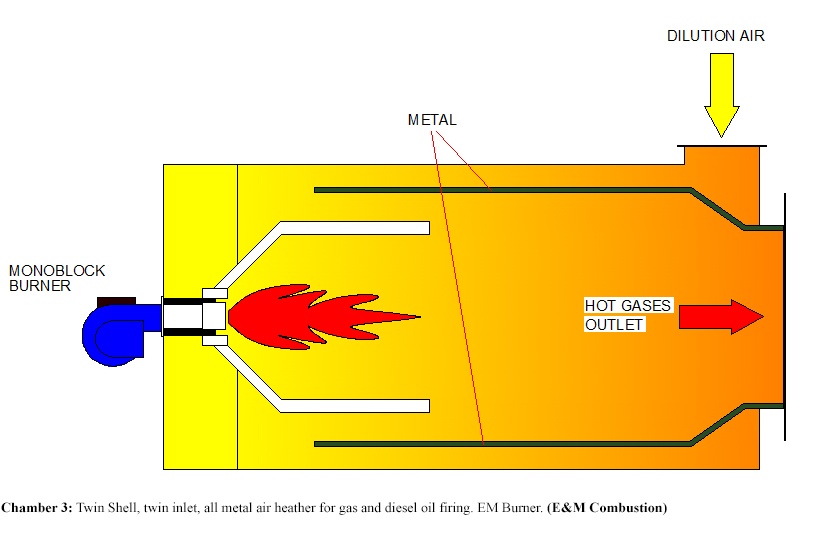

On the one hand, it would be the most traditional gas generator formed by a double chamber, one inside where the flame produced by a conventional burner with a combustion air fan would be located. Around this chamber it would be placed a second chamber through which circulates a dilution air that is mixed with these gases at the end of the internal combustion chamber obtaining the desired temperature.

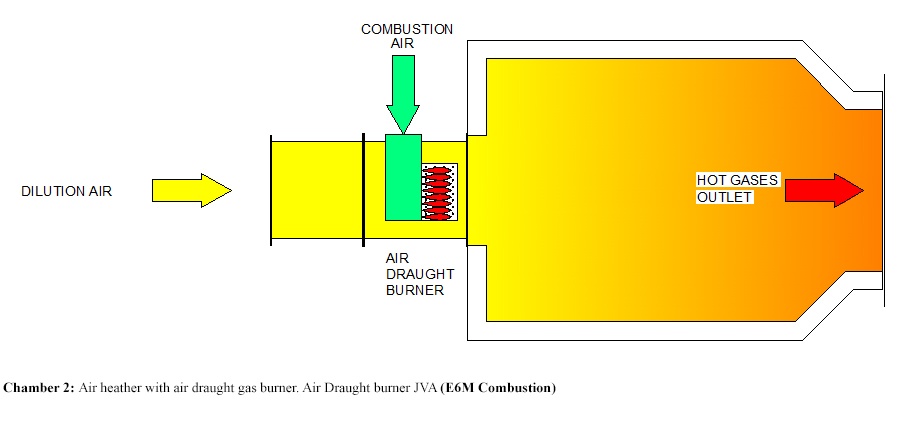

And on the other hand we have the option to use duct burners whose operating principle is that the air passes through them and is heated to the desired temperature. These burners can work with a high excess of air which means that it is not necessary to use a second chamber through which the dilution air circulates.

Advantages of duct burners over traditional forced air

• Less pressure drop.

• More optimized design.

• More linear air regulation.

• Shorter combustion chambers.

• Less weight of materials.

• Shorter flames.

Materials to be used in Hot Gas Generators

E & M Combustion manufactures all of its burners and combustion chambers using high quality materials such as high quality AISI 310 refractory steels for flame-sensitive burner areas or refractory material resistant to temperatures of 1,650 ° C where there is a risk of where the flame can touch the chamber.

Automation and energy saving

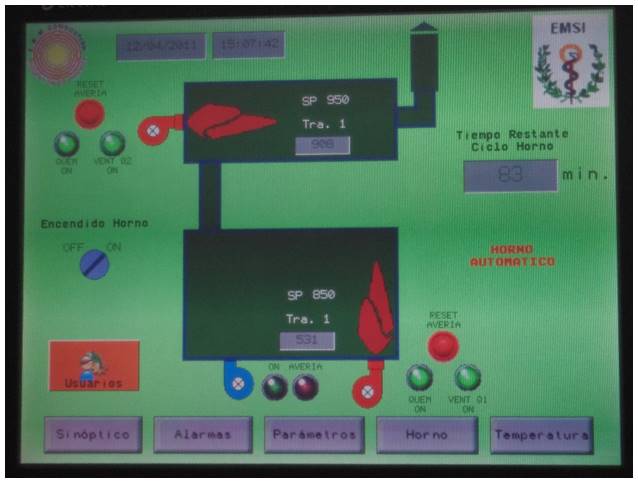

The hot gas generators designed by E & M Combustion operate in a completely automated way. E & M Combustion designs and installs in the compact unit the electrical boxes in which it integrates the regulation systems that allow the automatic and precise operation of the system.

The burners use electronic control units which have the following advantages.

• All control and regulation functions are integrated in one single device, including sequences of ignition, security controls, P.I.D regulation, leakage test and flame detection System

• It remarkable increases the precision of the regulation, avoiding mechanical hysteresis produced in rods and cams of the traditional regulation

• This is operated by the transmission of electrical pulses to individual actuators

• It incorporates a visualization display of information that can quickly show the state of the burner as well as fault memories and hours of operation

• Presents and external connection to P.C. or to P.L.C. bus system

• Reduces time of commisioning due to pre-regulations in the factory

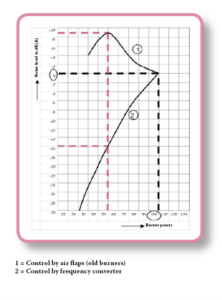

These switchboards also allow the use of frequency inverters to save electricity. The inverters generate a saving of electrical energy and reduction of the level of noise that can be quantified in the graph of the figure.