News | Industrial Combustion Equipment

All the latest News on our company

The most impressive images of the Ashalim Thermosolar Power Plant from a drone view

Posted on: 05 / 05 / 2020 | 0 Comentarios | Tags: Ashalim Solar Thermal Power, Burners for Solar Thermal plants, Concentrate solar power, E&M Combustión, Quemadores para centrales termosolares

The Ashalim Thermosolar Power Plant is already fully operational in the Negev desert in Israel where it generates renewable energy for 60,000 households.

The plant is one of the largest projects of its kind in the world and has become the first thermal solar plant with technology Concentrate Solar Power (CSP) developed by General Electric and its technological partner Brigh Source Energy, with an investment of 1,000 million Dollars.

The facility serves 60,000 households and represents the equivalent of 2% of the country’s consumption, thus approaching its goal of producing 10% of energy through renewable energy from 2020.

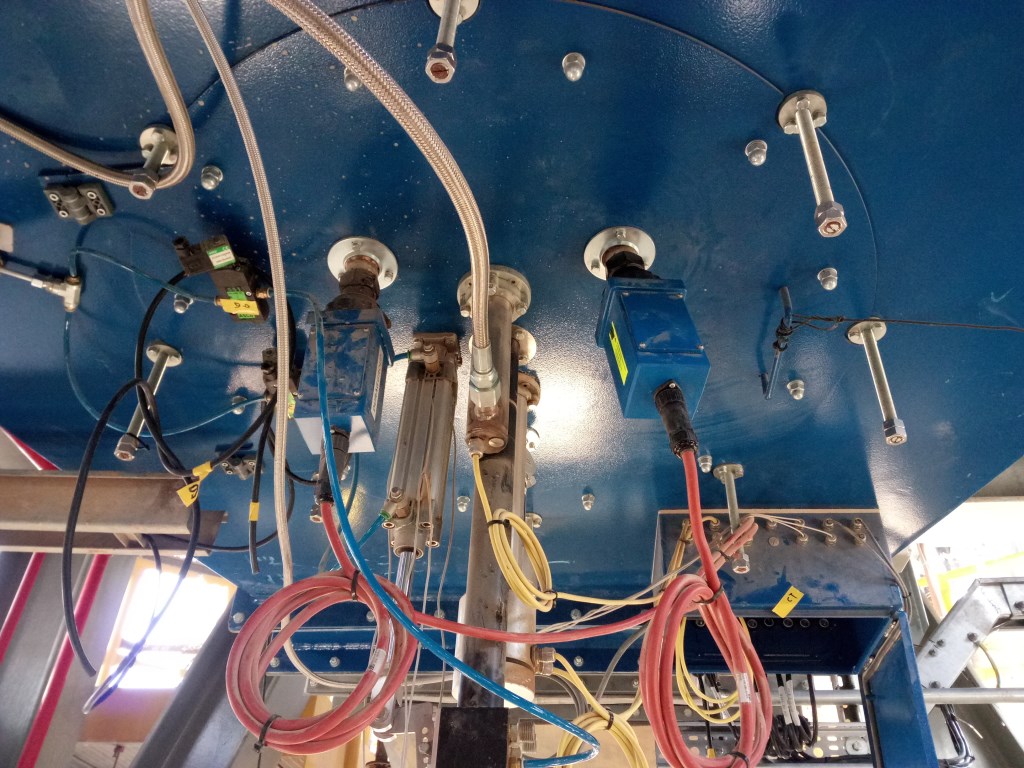

E&M Combustion provides this project with a technical solution aimed at optimizing the combustion process and reducing pollutant emissions, with the supply of 5 large industrial burners, as well as a Flue Gas Recirculation system (F.G.R.). For its part, the Sugimat company has manufactured 5 large 25 MW thermal boilers for this project.

Thus, for the Ashalim solar thermal power plant, E&M Combustion has designed and manufactured three JBD-60,000-G industrial burners, which will run on natural gas, and two other JBD-60,000-GLO burners, which will operate on diesel and natural gas. The five combustion units will work with air preheated to 250ºC and with a Flue Gas Recirculation system (F.G.R.) to reduce NOx emissions below 100 mg / Nm3 in the combustion of natural gas.

The use of preheated air in the burners makes it possible to significantly improve the performance of the plant, but at the same time increases emissions by increasing the flame temperature. The technical solution provided by E&M Combustion engineers has been able to counteract the increase in emissions by implementing a flue gas recirculation system (FGR), which optimizes combustion by lowering the flame temperature, causing also decrease the thermal NOx.

Have a look to the most impressive images of the Ashalim Solar Thermal Power Plant Video