News | Industrial Combustion Equipment

All the latest News on our company

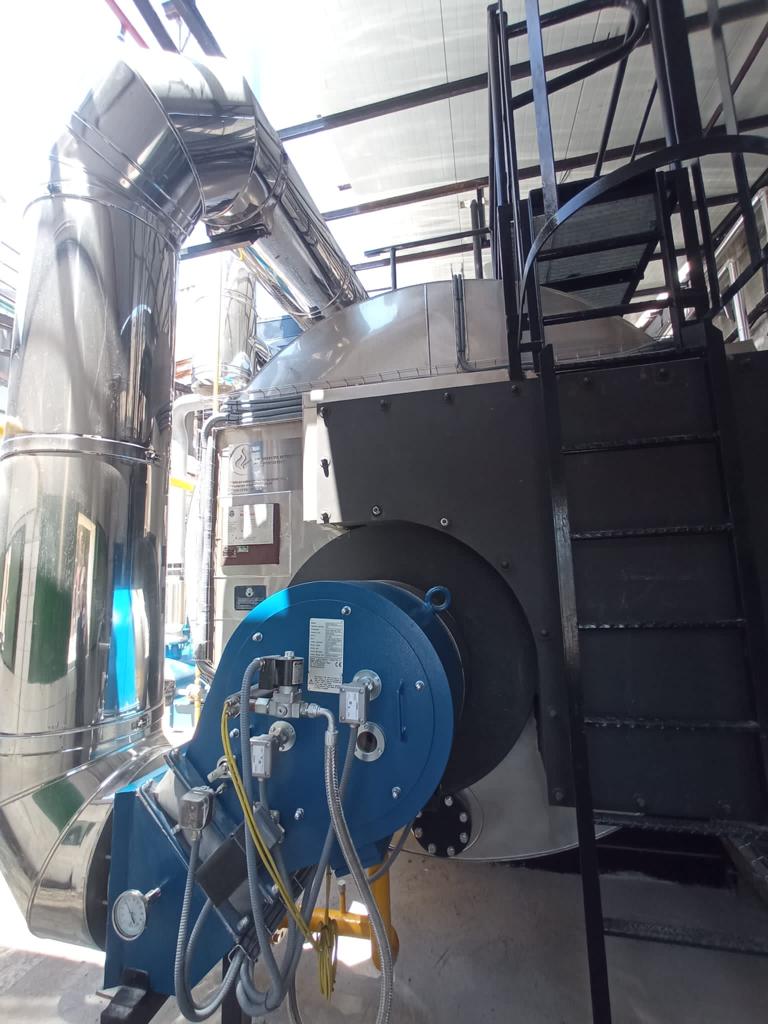

Low NOx burner in a paper mill to reduce emissions

Posted on: 31 / 07 / 2022 | 0 Comentarios | Tags: Adaptación a la normativa medioambiental, Adaptation to environmental regulations, eficiencia energética, Energy Efficency, Low Nox Burner, quemadores Low Nox

E&M Combustiónhas installed a Low NOx burner in a paper plant with the aim of reducing the environmental impact of the factory’s emissions, improving its energy performance, and adapting to the new European environmental regulations.

The Low NOx burner designed and manufactured by E&M Combustión, development engineering for thermal combustion systems, is a piece of equipment from the JBD 6000 family designed to work with high overpressures in the combustion chamber and prepared to operate with hot air at 100ºC.

The implementation of the Low NOx burner has been aimed at optimizing the performance of the boiler room of the aforementioned paper production plant. Among its objectives is the reduction of the fuel consumption of the installation, with the corresponding expected energy savings, as well as the adaptation to the European environmental regulations for the reduction of emissions into the atmosphere. In fact, the implementation of the E&M Combustión Low NOx burner, together with the start-up of a combustion flue gas recirculation system, has made it possible to achieve NOx emissions with natural gas below 60 mg/Nm3, thus exceeding even the most demanding regulations currently established by the European Union. The start-up of the equipment has been carried out by Soluciones Integrales de Combustion.

Characteristics of the low NOx burner

JBD burners are combustion equipment capable of operating with any type of liquid and gaseous fuels, both with traditional fuels and mixed burners that work with several fuels at the same time or intermittently, and renewable fuels, such as hydrogen or biogas. In this project, the burners replace traditional fuels with equipment that works with natural gas.

JBD burners are duoblock units that use double air registers and are capable of achieving different flame lengths and shapes depending on the air registers. These combustion equipment can use different types of heads, so that their flames can be adapted to the different homes and combustion chambers where they will have to operate.

These burners can be regulated from standard electronic control units that allow the use of frequency variators to regulate the fan and O2 sensors.

Low emission burner

E&M Combustión works continuously to achieve more energy efficient combustion equipment, through the development of R&D projects and the creation of innovative prototypes. It is also characterized by an agile adaptation of its designs to the needs of customers. The objective is to seek the highest energy efficiency and the lowest level of polluting emissions.

With the aim of improving energy efficiency, the company carries out energy saving audits and studies at the plants that incorporate combustion equipment. These studies allow evaluating the return on investment through the installation of more efficient industrial burners, as well as combustion optimization equipment and frequency inverters for fans, among others.

The company makes its Low NOx technology available to customers to be able to carry out conversions, modifications and replacement of existing combustion systems with others with lower levels of emissions, in order to adapt to the challenge of protecting and conserving the environment.