News | Industrial Combustion Equipment

All the latest News on our company

European fluid-dynamic computational R&D&I project to design hydrogen burners

Posted on: 08 / 03 / 2024 | 0 Comentarios | Tags: Combustión de hidrógeno, E&M Combustión, Proyecto computacional fluidodinámico, Proyecto de I+D+i de quemadores de hidrógeno

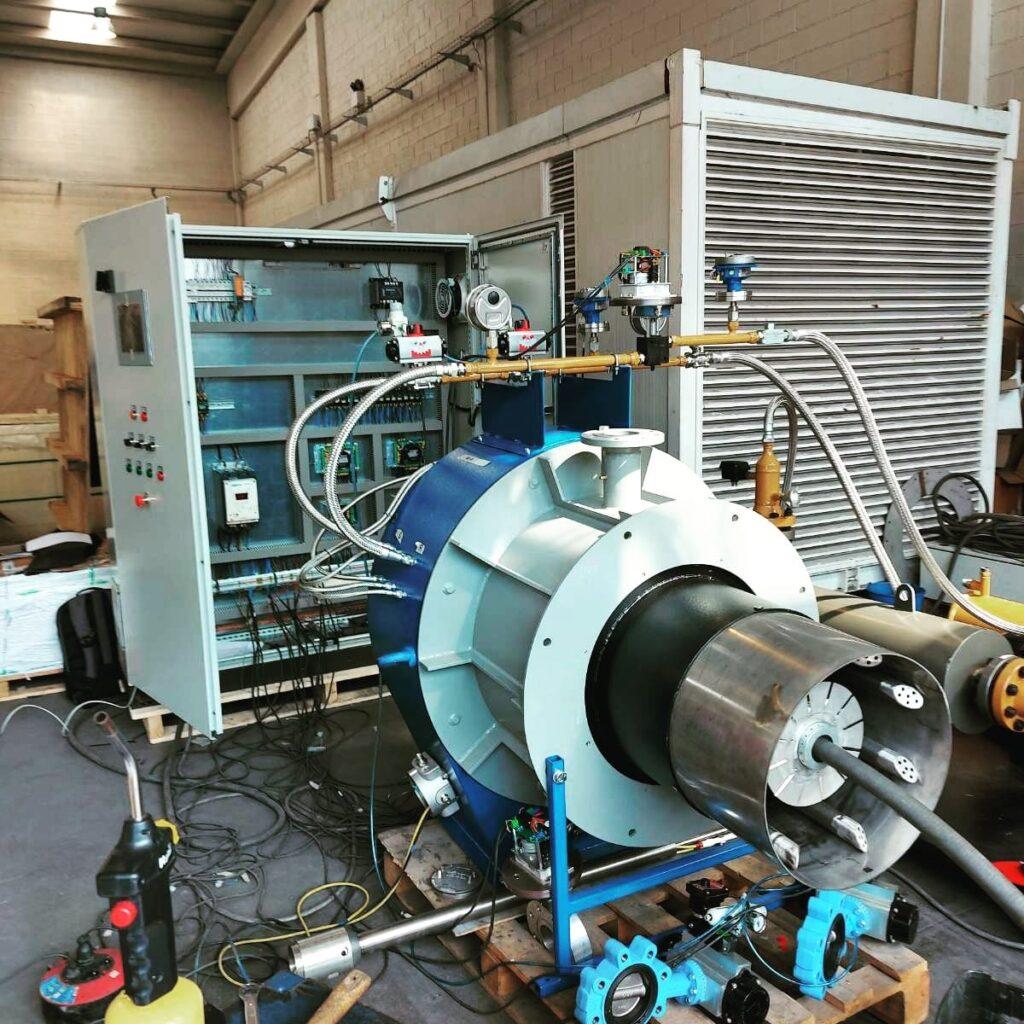

E&M Combustión (E&MC) completes, together with the Barcelona Supercomputing Center (BSC), the development of a computing project to design hydrogen burners. The European R&D&i project has led to the creation of fluid-dynamic computational modeling software for hydrogen burners, through the use of High Performance Computing (HPC).

The software will be responsible for simulating, predicting and validating on the computer the parameters of the hydrogen combustion conditions with which the equipment will operate, and will do so with the highest degree of reliability.

The digitalization project developed by EMC and BSC has allowed the development of a virtual test platform for industrial burners, which use HPC technology in order to obtain quantitative and qualitative information on combustion performance, in terms of combustion dynamics of the flames, formation of contaminants and operation of hydrogen burners.

The trials have combined physical tests and “high-fidelity” numerical simulations, with the aim of aligning with the European goal of accelerating the deployment of low-carbon energy generation while, at the same time, reducing duration and costs of the design phases.

The platform will now be integrated into E&M Combustion’s design and optimization cycle for its new low-NOx burners that operate with hydrogen. In this way, the use of the system will allow a great reduction in the time spent in the traditional phases of calculation, design and manufacturing of the prototype, testing in real situations, rectification of prototypes and manufacturing of the equipment, shortening time to market.

Computing project to design hydrogen burnersr

The European FF4EuroHPC program has contributed its funding to the development of the computing project to design hydrogen burners, which it has defined as a Success Story, which is why it recommends its dissemination in the European industrial network, since it considers the use of digitalization based on advanced simulations enabled with HPC technology to increase the competitiveness of SMEs. FF4EuroHPC is the European program in charge of connecting the industry with innovative technologies in the field of High Performance Computing and the application of Artificial Intelligence

E&M Combustión can thus benefit from a computational platform for virtual testing of industrial burners using HPC (a technology that uses clusters of powerful processors working in parallel to process massive data sets), which will result in significant cost savings associated with traditional physical testing, reducing the need for expensive prototypes, as well as test equipment and reducing the time spent by specialized personnel on these tasks.

With virtual testing, E&MC will be able to accelerate the development of new industrial burners, achieve faster time to market, and gain a competitive advantage and higher productivity. Additionally, the computational platform will allow the company to achieve improvements in innovation, as it will test new and innovative combustion chamber designs that may not have been feasible with traditional testing methods, reducing consumption and fossil emissions from these methods.

According to estimates, as a result of the R&D&I project, the company will be able to shorten production time and time to market by 20%, as well as continue acquiring knowledge in hydrogen technologies, and reduce maintenance costs by 25% through this numerical simulation. On the other hand, the digitalization of burner design will make it possible to reduce design costs by 30% and labor costs by 5%.

Prioritization of low carbon technologies

The European Union’s commitment to achieving net zero greenhouse gas emissions by 2050 is driving the power generation industry to prioritize the development of low-carbon technologies.

Among the different solutions, green hydrogen and hydrogen-enriched fuels have significant potential to enable the transition to a clean, low-emission energy system – particularly with regard to NOx, creating challenges for all industries, particularly for SMEs. For this reason, the EU considers digitalization based on advanced simulations enabled with HPC (high-performance computing) technology with fluid dynamic simulations, known as CFD (acronym for Computational Fluids Dyanomics) to understand and predict the behavior of a system, key to increasing its competitiveness. fluid under certain conditions.

Application of cutting-edge technologies

The European initiative FF4EuroHPC provides SMEs with access to all technologies related to high-performance computing, which aims to increase the innovation potential of European industry. FF4EuroHPC connects companies with cutting-edge technologies, running high-resolution simulations, performing large-scale data analysis or incorporating artificial intelligence applications into SME workflows.

Within the FF4EuroHPC programme, European SMEs can develop unique products, innovative business opportunities and become more competitive by using high-end European HPC services. Through the project, two open calls have been offered so far, aimed at high-quality experiments involving innovative and agile SMEs.

The proposals presented have addressed the business challenges of European SMEs in various areas of application. Experiments that have met the standards of the open call have been carried out on cloud-based HPC systems, grouped into two tranches. The experiments consist of an end-user relevant case study, demonstrating the use of cloud-based HPC and the benefits it brings to the value chain. When the experiment concludes successfully, the result is a success story that inspires the industrial community.

The FF4EuroHPC program began at the beginning of September 2020 and has lasted for three years. The program is funded by the European Commission within H2020, the EU Framework Program for Research and Innovation, with a total budget of €9.9 million. It is coordinated by the University of Stuttgart (USTUTT, DE) and is made up of 5 other partners: Scapos AG (DE), Teratec (FR), CINECA (IT), CESGA (ES) and Arctur (SI).

Barcelona Supercomputing Center

To carry out the European R&D&I project for hydrogen burners, E&M Combustión, end user of the research project, has collaborated with the Barcelona Supercomputing Center (BSC), through the Propulsion Technologies working group , which works on computational models for energy and propulsion applications.

E&M Combustión

E&M Combustion is a Spanish thermal engineering company that develops customized solutions for industrial combustion systems and thermal power plants. Application fields include power generation, oil and gas, steel and metal, and food and beverage industries. E&MC develops burners for power production plants to operate with all types of liquid and gaseous fuels, from diesel or natural gas to alternative fuels, such as biogas and hydrogen.