News | Industrial Combustion Equipment

All the latest News on our company

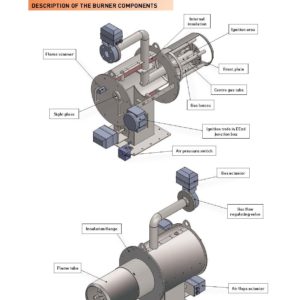

Description of a Gas Burner Components

Posted on: 27 / 10 / 2018 | 0 Comentarios | Tags: Burner, Burner components, Descripción componentes quemador, Description of burnes components, E & M Combustion, E&M Combustión, EExd junction box, gas burner, Gas burners components, industrial burners, Partes de un quemador, quemador, quemador de gas, quemadores industriales

Description of a Gas Burner Components. Industrial Burners designed and manufactured by E & M Combustion.

Description of a Gas Burner Components. Industrial Burners designed and manufactured by E & M Combustion.

GAS BURNER COMPONENTS

- Flame Scanner

- Sight Glass

- Internal Insulation. An advantage of these burners is that they can work with preheated air up to a temperature of 400 ° C, therefore considerably increasing the combustion performance and the efficiency of the boiler. To avoid this heat to be transmitted to the outside, these burners carry an insulation around the housing that makes the temperature transmitted to the outside through this body not to exceed of 40 ºC. This insulation is covered by a stainless steel plate that protects it from any kind of damage or oxidation. The fact of carrying this insulation also supposes a reduction of the noise of the combustion.

- Ignition Area. El arranque o encendido en los quemadores, se realiza mediante un innovador sistema denominado C.I.S (Crown ignition system). La llama piloto se produce justo detrás del estabilizador, creándose ésta en forma de corona y de una manera uniforme alrededor del mismo. Este sistema presenta las siguientes ventajas sobre los convencionales: Reducción de las diferentes variaciones de presión. Reducción de las fluctuaciones de la llama. Suavidad y estabilidad en el arranque.

- Front Plate.

- Centre Gas Tube. Easy disassembly of the burner gas head, removing the front plate and the ignition electrodes easily as well as the gas lances.

- Gas Lances. The gas head is made up of a centre gas tube from which a series of lances come out in the outside and in the centre part. The gas distribution consists of 20 percent in the central ring and 80 % in the external lances, producing a combustion in stages, therefore achieving a significant reduction of NOx and greater flame stability.

- Ignition trafo in EExd junction box. Due to the heat transmitted in boilers using preheated air, especially where the burner is installed vertically, the transformer is installed and protected in an ATEX EExd junction box to prevent heat from affecting this element. Ignition cables are also covered and insulated to protect against temperature.

- Air Pressure Switch

- Insulation Flange

- Flame Tube. Easy disassembly of the flame tube. It can be removed without removing the burner.

- Gas Actuator

- Gas Flow Regulating Valve. The burner is controlled from the external control panel, which includes a switchboard for electronic regulation. This controls the different servo-motors for the adjustment of the air flaps and the butterfly valve for gas

- Air Flaps Actuator